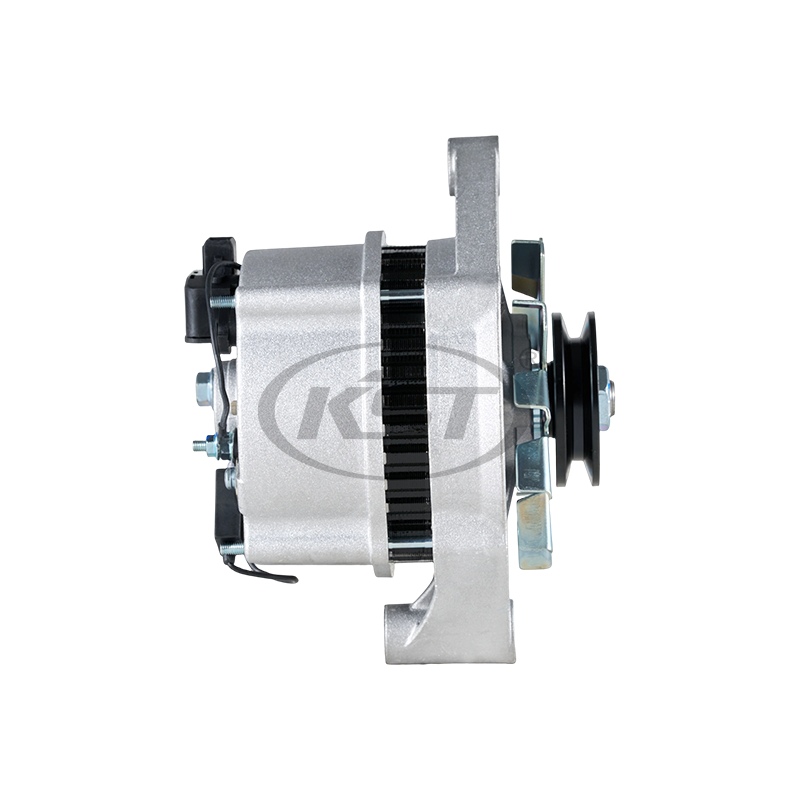

How to Choose the Correct Starter for an Excavator Engine?

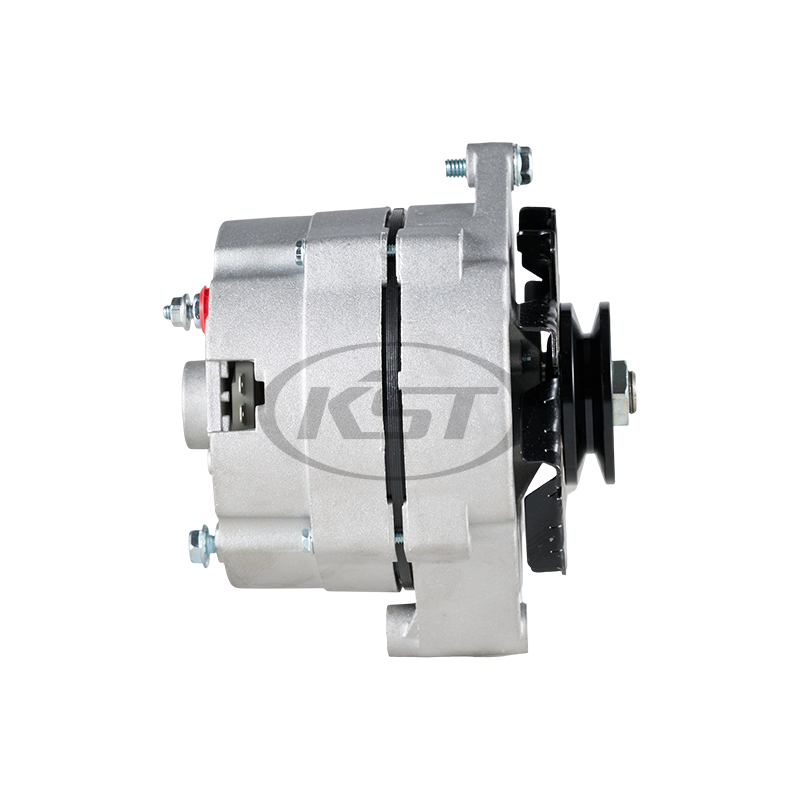

Selecting the correct Starter is critical to ensuring reliable engine ignition and long-term performance. From a manufacturing standpoint, this process starts with understanding the working conditions and engine configuration rather than simply matching part numbers.

Key selection factors include:

- Engine displacement and compression ratio

Larger excavator engines require a Starter with higher torque output to overcome compression resistance during cold starts.

- Rated voltage and power

Excavators typically operate on 12V or 24V systems. A mismatched Starter can cause slow cranking or premature failure.

- Mounting and gear engagement design

Precise alignment with the flywheel is essential. Professional manufacturers design each Starter housing to match specific engine interfaces.

- Duty cycle expectations

Excavators often experience frequent start–stop operations. A heavy-duty Starter with reinforced armature and solenoid structure is recommended.

From an Excavator Parts Factory in China, these parameters are validated through engine simulation testing to ensure the Starter performs consistently under real construction conditions. Proper selection reduces downtime, improves fuel efficiency, and extends service life.

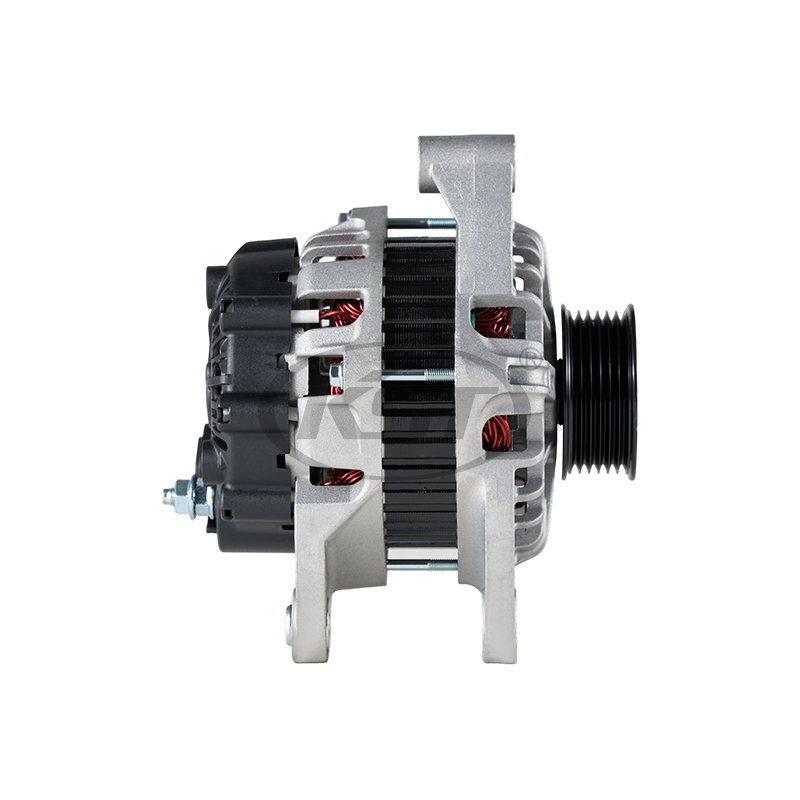

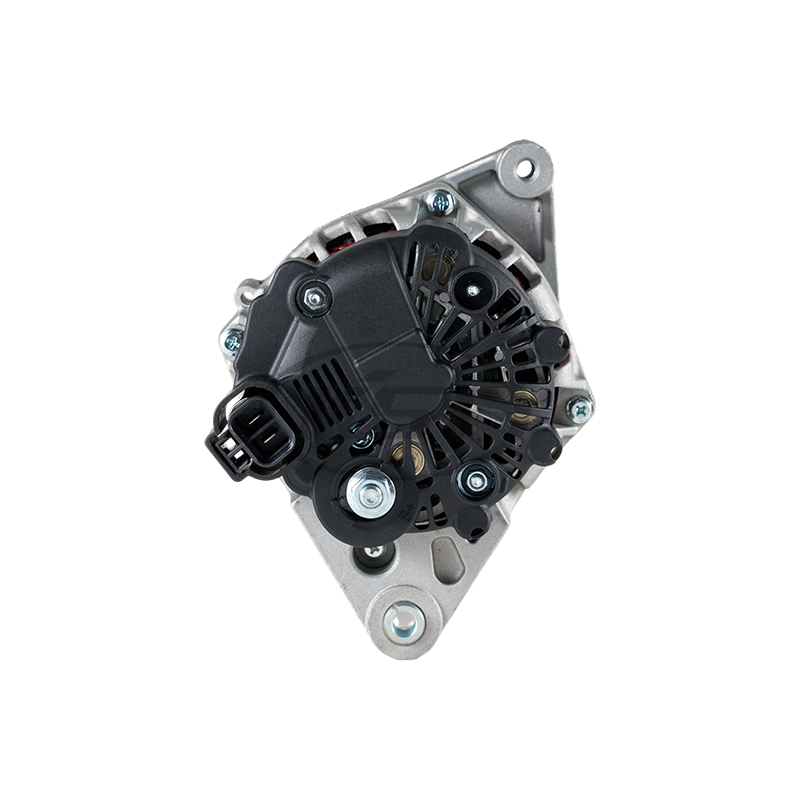

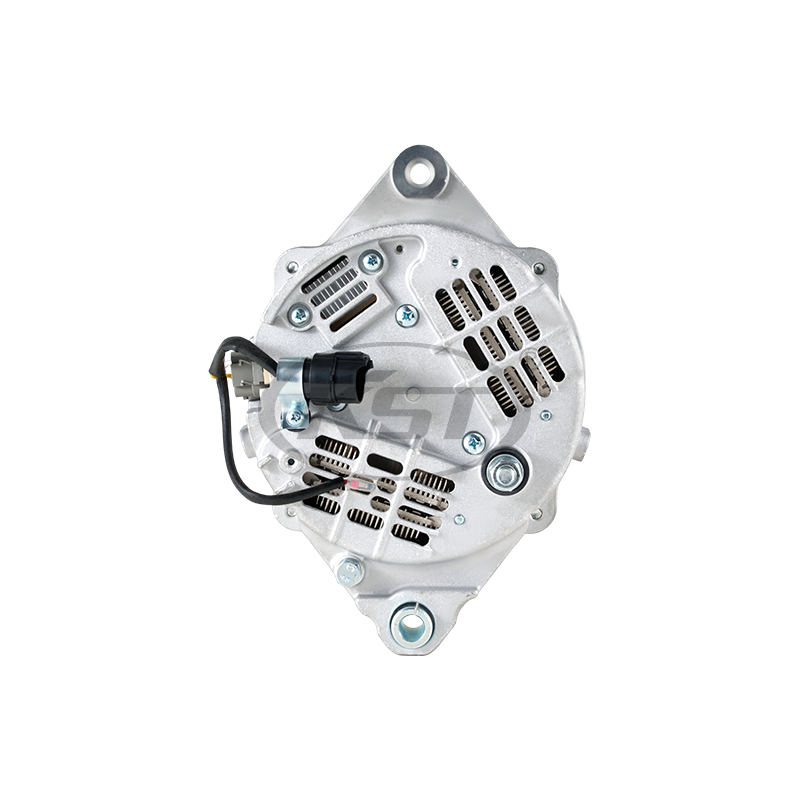

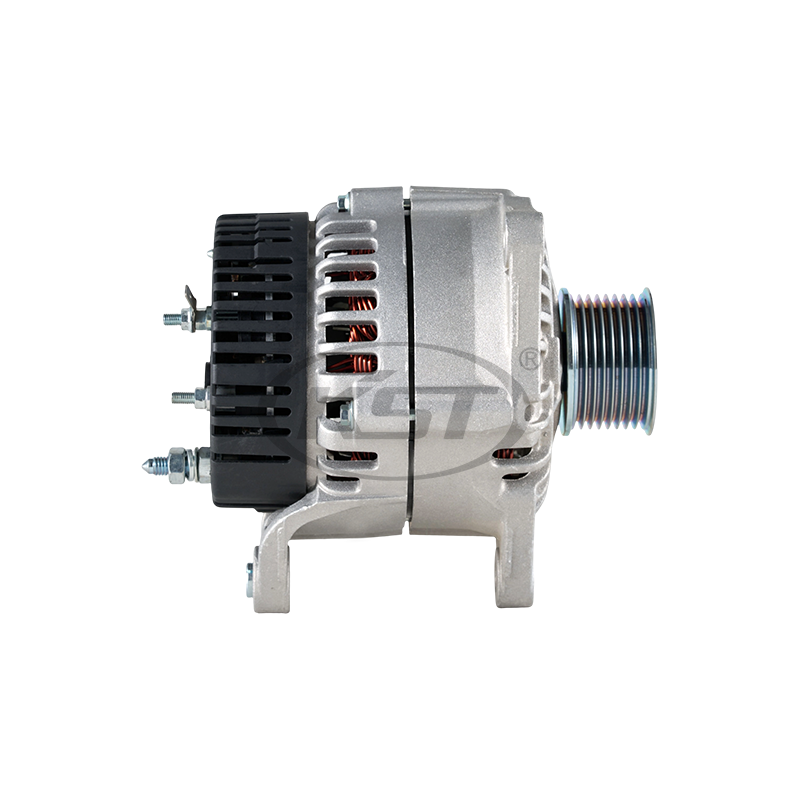

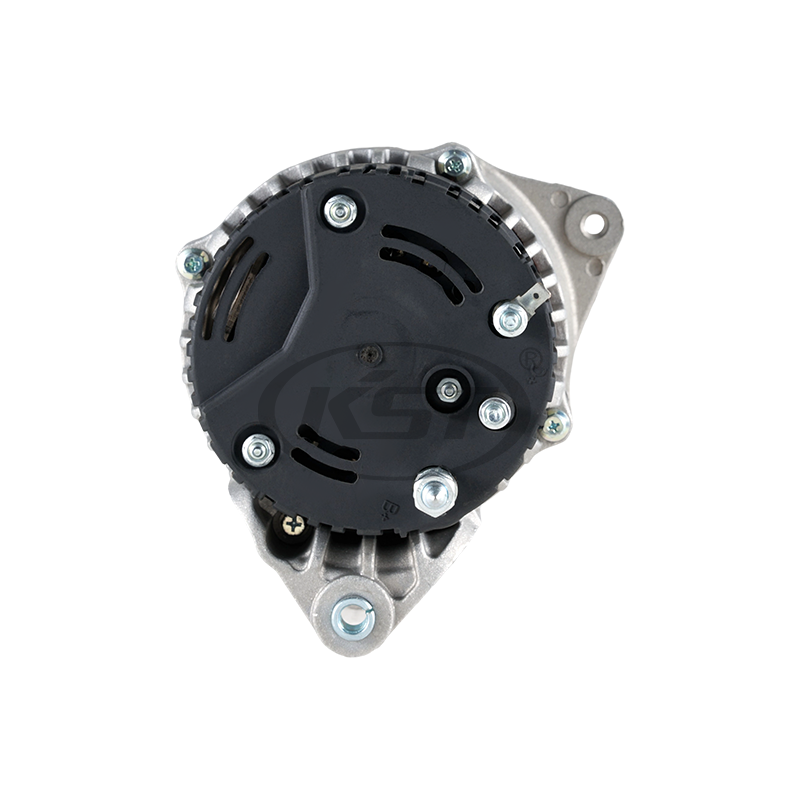

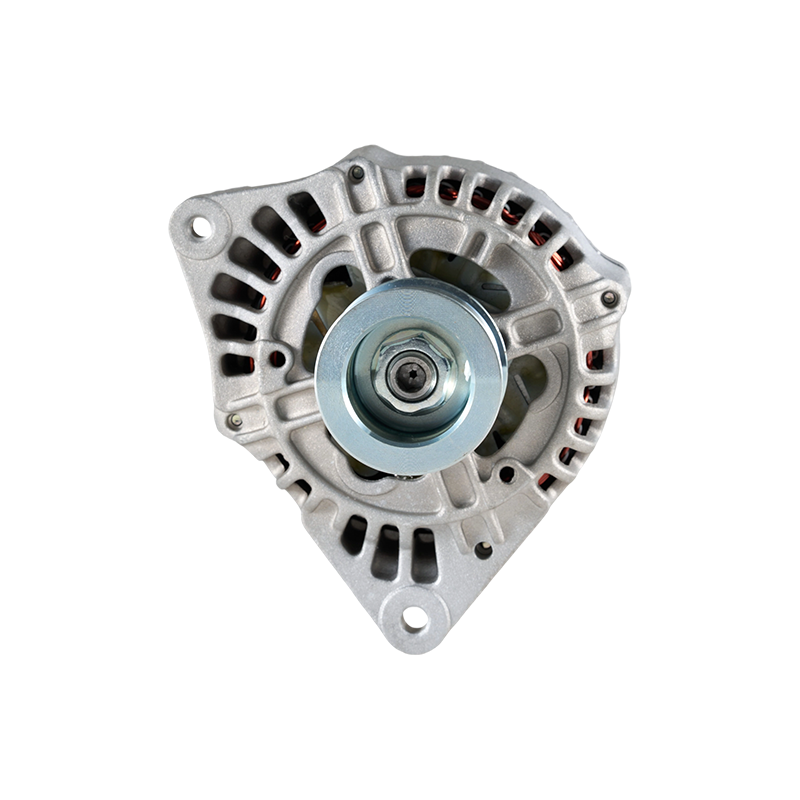

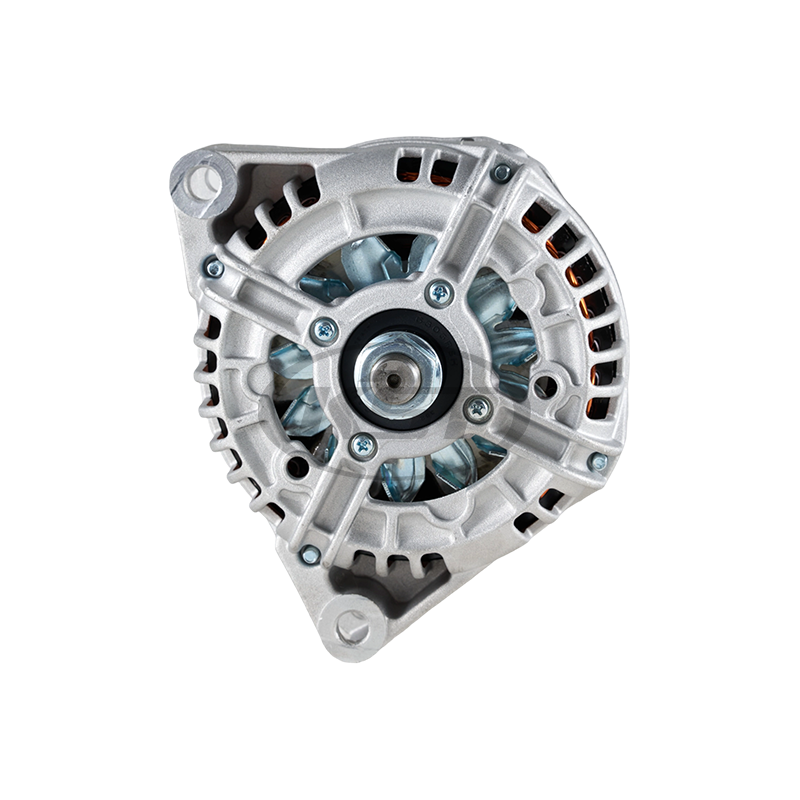

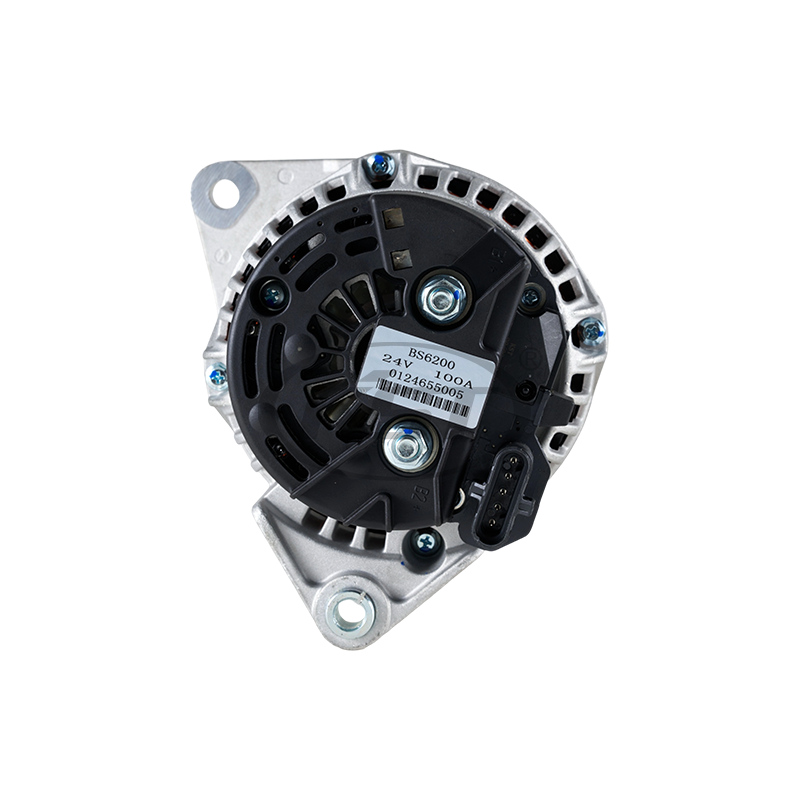

Copper Wire or Aluminum Wire Alternator Differences?

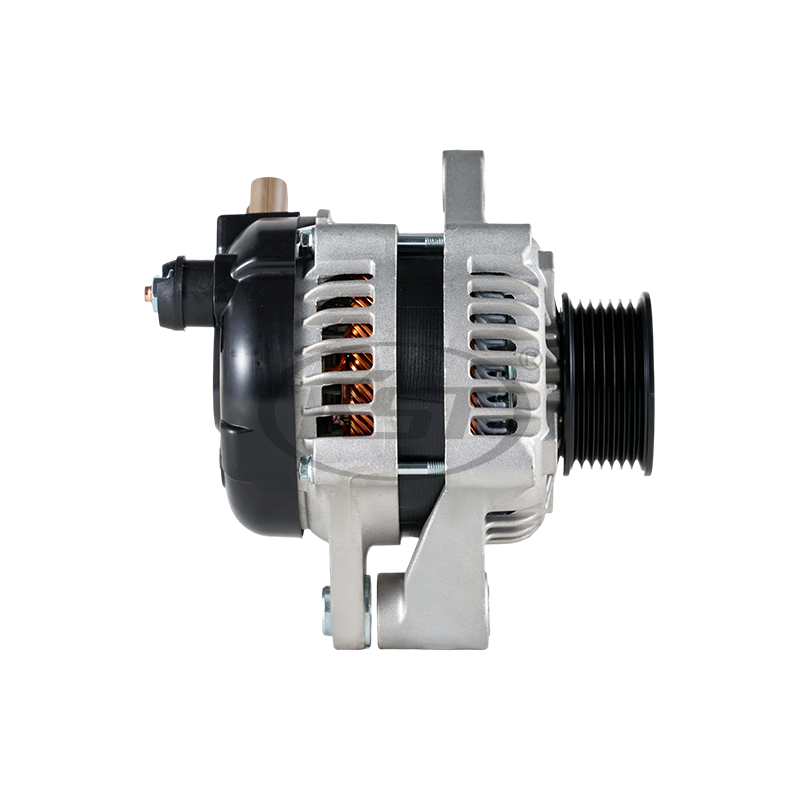

Choosing between copper-wound and aluminum-wound Alternator designs is a common concern for global buyers. Each option serves different operational priorities.

| Feature | Copper Wire Alternator | Aluminum Wire Alternator |

| Electrical conductivity | Higher | Lower |

| Heat resistance | Excellent | Moderate |

| Weight | Heavier | Lighter |

| Service life | Longer | Shorter |

| Cost | Higher | Lower |

From a manufacturing perspective, a copper-wound Alternator is preferred for excavators working long hours with multiple electrical loads such as lighting, sensors, and control units. Aluminum-wound Alternator models may be suitable for lighter applications or cost-sensitive markets.

A professional Excavator Parts Factory in China typically offers both configurations, allowing customers to balance durability and budget without compromising system compatibility.

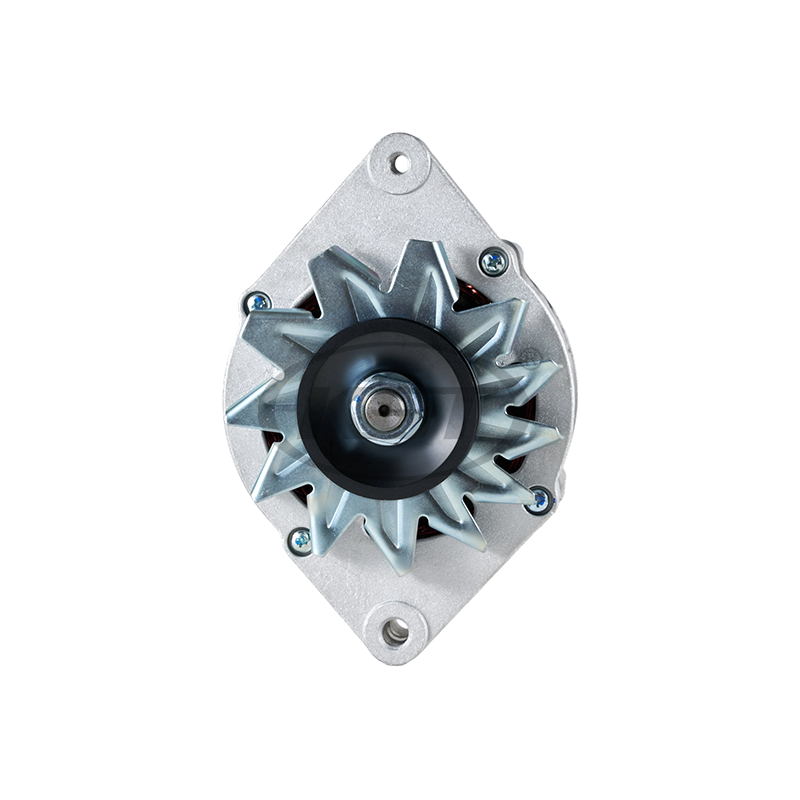

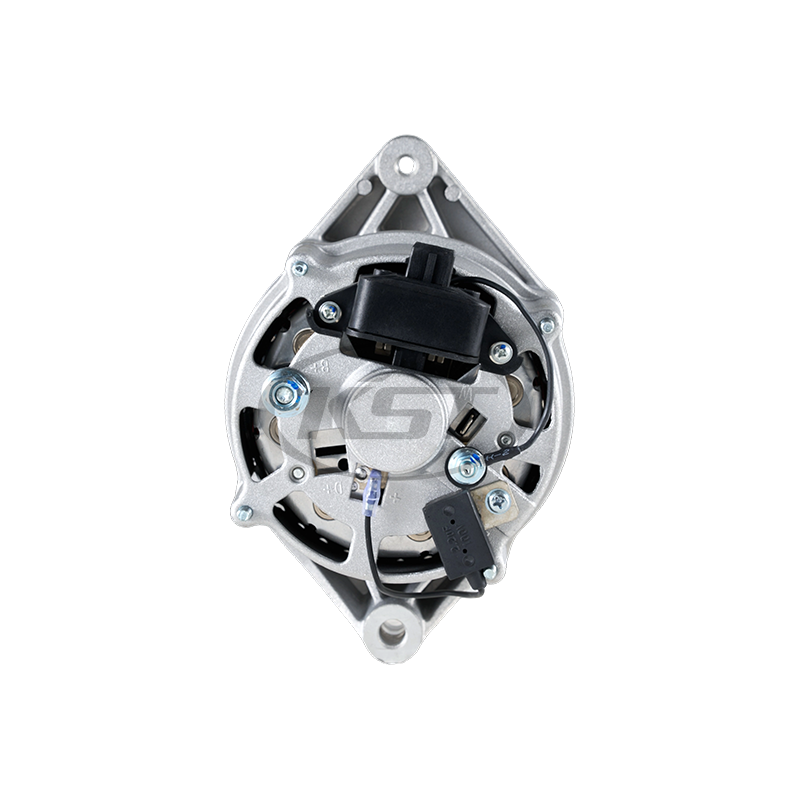

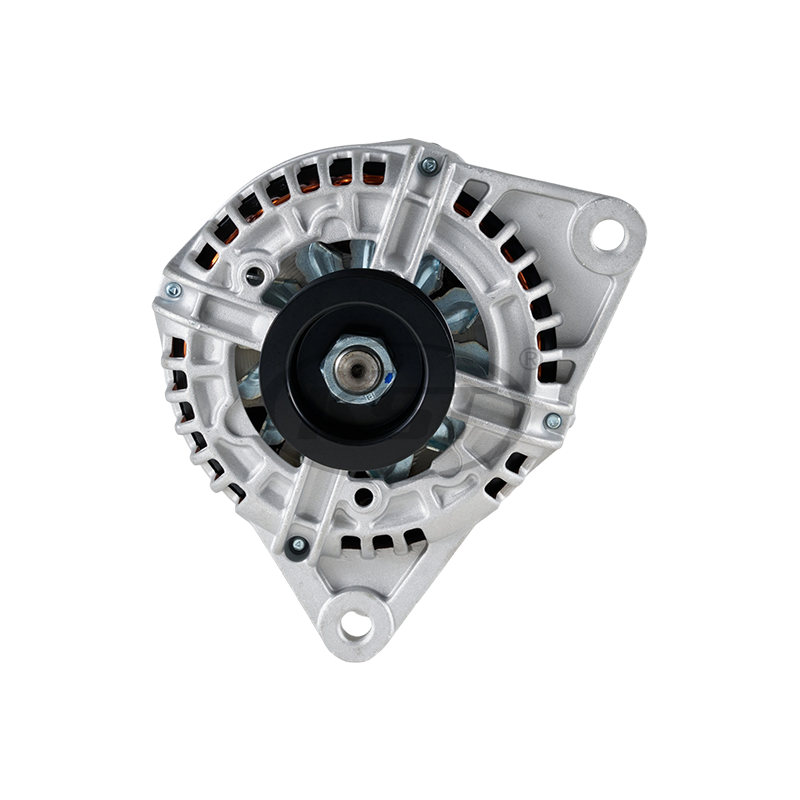

Alternator Performance Under Harsh Working Conditions?

Excavators operate in some of demanding environments, including high dust levels, vibration, humidity, and temperature extremes. Under these conditions, Alternator design quality becomes a decisive factor.

Performance factors engineered by manufacturers:

- High-temperature insulation systems to prevent winding degradation

- Sealed bearings to resist dust and mud intrusion

- Enhanced cooling structures to stabilize output during continuous operation

- Voltage regulation stability to protect onboard electronics

In a professional production environment, each Alternator undergoes load testing, vibration simulation, and thermal aging analysis. A well-designed Alternator maintains stable current output even when the excavator runs extended shifts under full load.

This focus on durability is a defining feature of a reliable Excavator Parts Factory in China, where alternator performance is verified against real construction scenarios rather than theoretical specifications.

How to Verify Excavator Parts Factory Quality Control?

For international buyers, verifying quality control is just as important as product specifications. A reputable Excavator Parts Factory in China demonstrates transparency across every production stage.

Key quality verification points:

- Incoming material inspection

Copper wire purity, bearing tolerance, and casting strength are tested before assembly.

- In-process quality control

Each Starter and Alternator is inspected during winding, assembly, and balancing.

- End-of-line functional testing

Products are tested for voltage stability, torque output, and noise levels.

- Traceability systems

Batch numbers allow manufacturers to track components back to raw materials.

From a manufacturer's perspective, consistent quality control ensures that every Starter and Alternator shipped meets global reliability expectations. Buyers working with an experienced Excavator Parts Factory in China benefit from reduced warranty risk, stable supply, and long-term cooperation potential.

From engine ignition to power generation, the coordination between Starter and Alternator systems defines excavator reliability. A professional Excavator Parts Factory in China does not simply supply components; it engineers complete solutions based on real-world machinery demands. By focusing on correct selection, material integrity, performance testing, and transparent quality control, manufacturers help customers achieve consistent performance across diverse construction environments.

Whether choosing a robust Starter, evaluating Alternator materials, or auditing factory processes, informed decisions cause longer equipment life and higher operational efficiency.

en

en  English

English عربى

عربى فارسی

فارسی

+86-18967073588

+86-18967073588