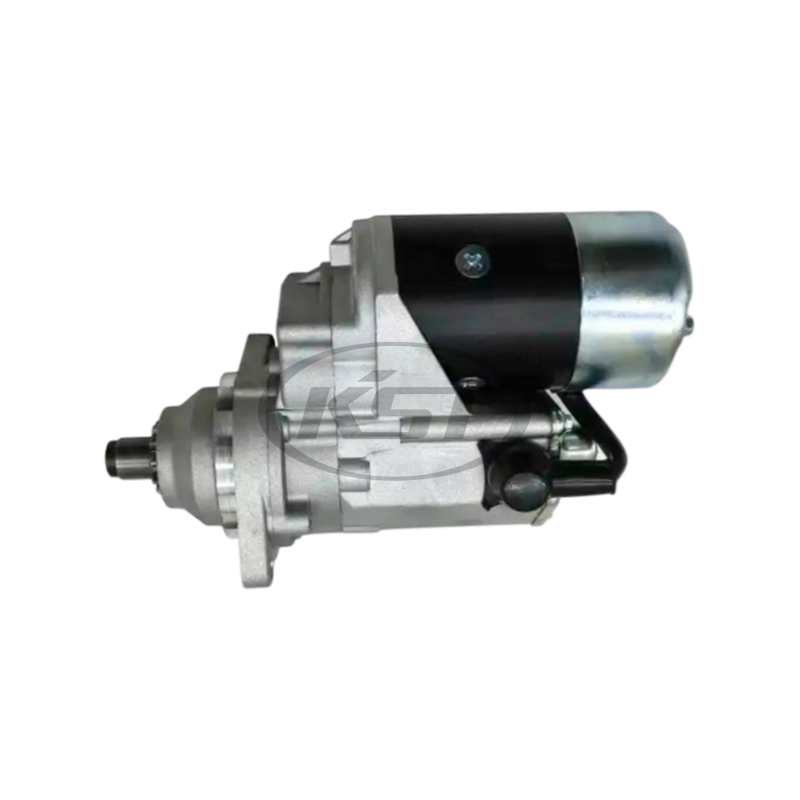

Why Are Premium Materials Critical

A Construction Machinery Alternator relies on high-quality copper, steel, and reinforced alloys to deliver conductivity and mechanical strength. These materials enable the alternator to endure frequent start-stop cycles, heavy loads, and temperatures common in construction machinery. By using durable components, a Construction Machinery Alternator minimizes wear and corrosion, ensuring reliable long-term performance even under the conditions.

How Does Precision Design Improve Performance

Design is a crucial factor for a Construction Machinery Alternator. Each unit is engineered for exact voltage output, torque, and compatibility with various machinery models. A well-designed Construction Machinery Alternator ensures smooth engine ignition and stable power supply, reducing strain on batteries and electrical systems. Precision engineering enhances operational efficiency, prevents downtime, and maintains peak machine performance on demanding construction sites.

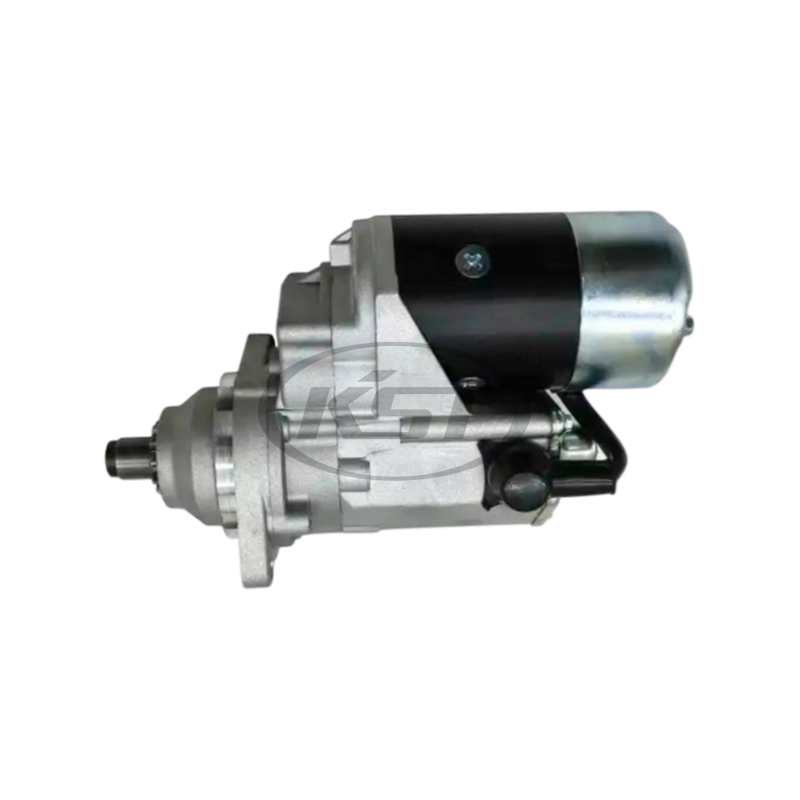

What Role Does Advanced Manufacturing Play

Modern Construction Machinery Alternator manufacturers employ CNC machining, automated coil winding, heat treatment, and precision assembly to guarantee consistent quality. Each alternator undergoes rigorous inspection for voltage stability, torque performance, and mechanical integrity. Streamlined production allows a Construction Machinery Alternator supplier to meet high-volume demands while maintaining reliability and uniform performance for industrial clients worldwide.

Why Is Quality Control Essential

Quality assurance is a cornerstone of Construction Machinery Alternator production. Alternators undergo tests for electrical output, mechanical durability, thermal resistance, and long-term reliability. Any deviations are immediately corrected to meet stringent industry standards. Through comprehensive quality control, a Construction Machinery Alternator manufacturer ensures every unit provides dependable performance, minimizes repair costs, and extends the life of construction equipment.

Can Customization Meet Unique Operational Needs

A Construction Machinery Alternator supplier offers customization options for voltage ratings, mounting configurations, reinforced components, and specialized coatings for harsh environments. Customized solutions from a Construction Machinery Alternator manufacturer allow repair shops and construction companies to meet unique operational requirements. Tailored designs improve efficiency, reduce downtime, and ensure compatibility across different machine models and work conditions.

How Does Proper Maintenance Extend Lifespan

Maintenance significantly influences the longevity of a Construction Machinery Alternator. Regular inspection, cleaning, and lubrication of mechanical parts prevent overheating, wear, and electrical failures. Well-maintained alternators continue to operate efficiently, supporting reliable engine starts and stable power delivery. A high-quality product from a Construction Machinery Alternator supplier ensures minimal downtime and long-term value for construction operations.

Why Are Sustainable Practices Important

Sustainability is increasingly significant in Construction Machinery Alternator production. Manufacturers adopt energy-efficient techniques, recycle materials, and reduce chemical usage to minimize environmental impact. By combining durability with eco-conscious practices, a Construction Machinery Alternator delivers reliable performance while supporting environmentally responsible industrial operations, which is increasingly valued in modern construction projects.

How Does Logistics Impact Delivery Efficiency

Timely delivery and logistics efficiency are vital for a Construction Machinery Alternator supplier. Coordinated transport, secure packaging, and organized inventory management ensure that alternators reach construction sites, repair workshops, and distributors quickly. Tracking industry trends and customer feedback allows a Construction Machinery Alternator manufacturer to adapt production schedules, designs, and capacities to meet changing market demands effectively.

What Are Emerging Trends and Applications

The demand for Construction Machinery Alternator continues to rise in the construction, mining, and industrial machinery sectors. Modern alternators feature reinforced components, improved energy efficiency, and compatibility with multiple machine types. Innovative Construction Machinery Alternator manufacturers are exploring advanced designs and materials to provide versatile, durable, and high-performance alternators that meet evolving industry needs worldwide.

en

en  English

English عربى

عربى فارسی

فارسی