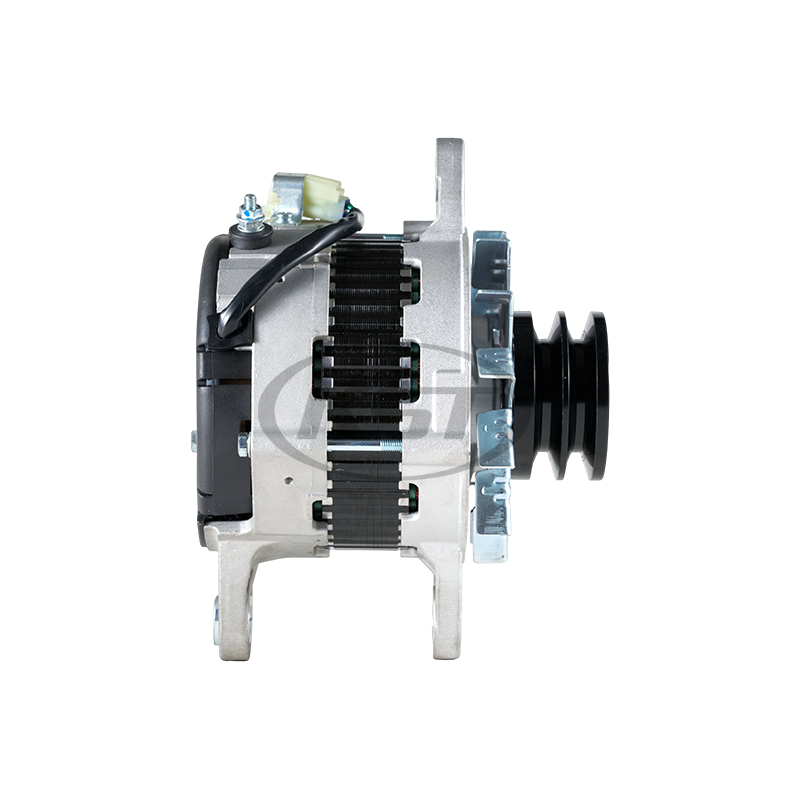

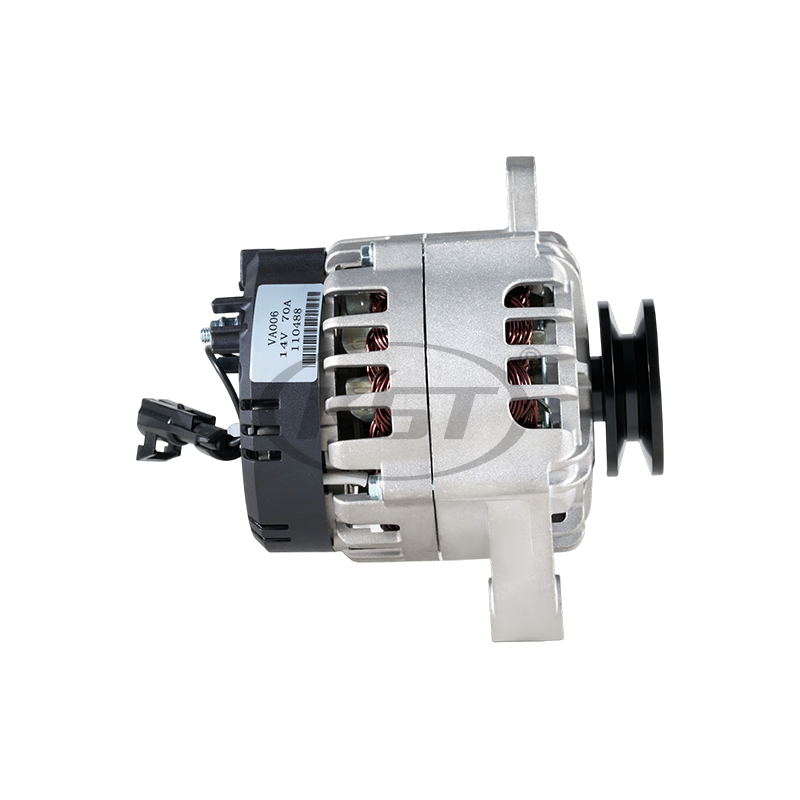

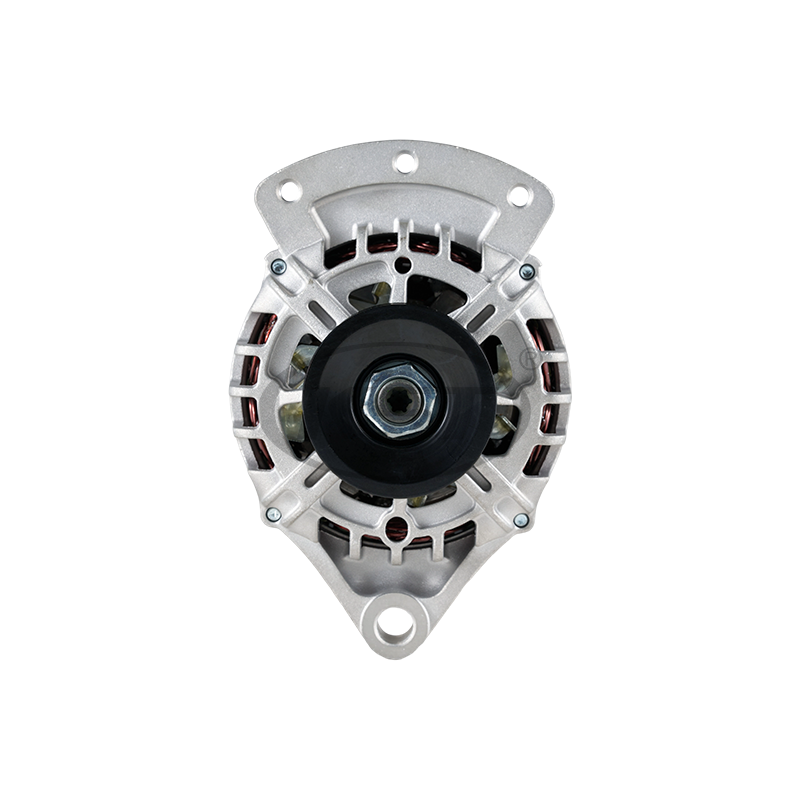

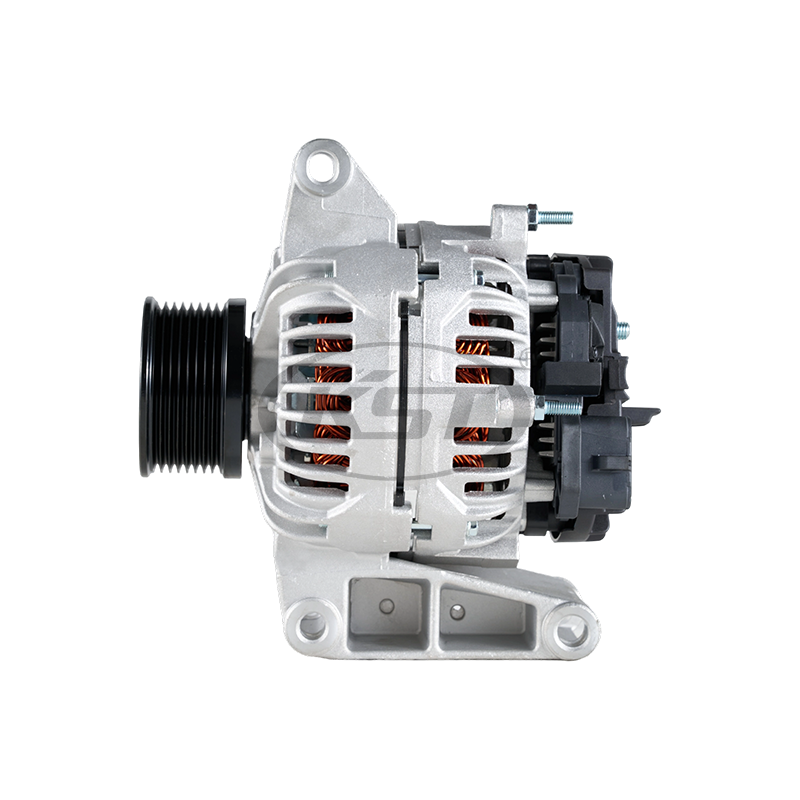

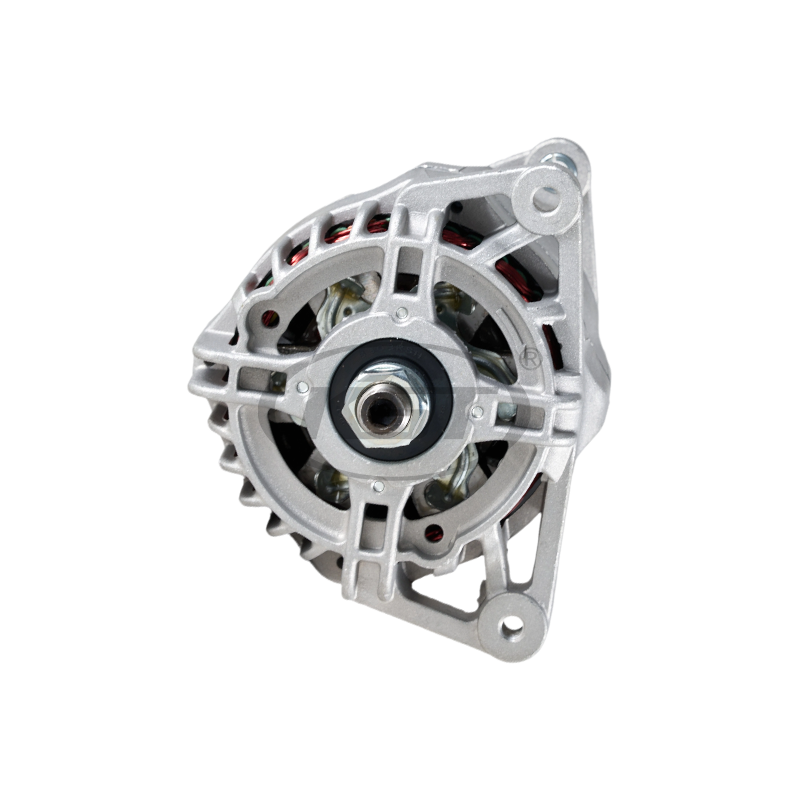

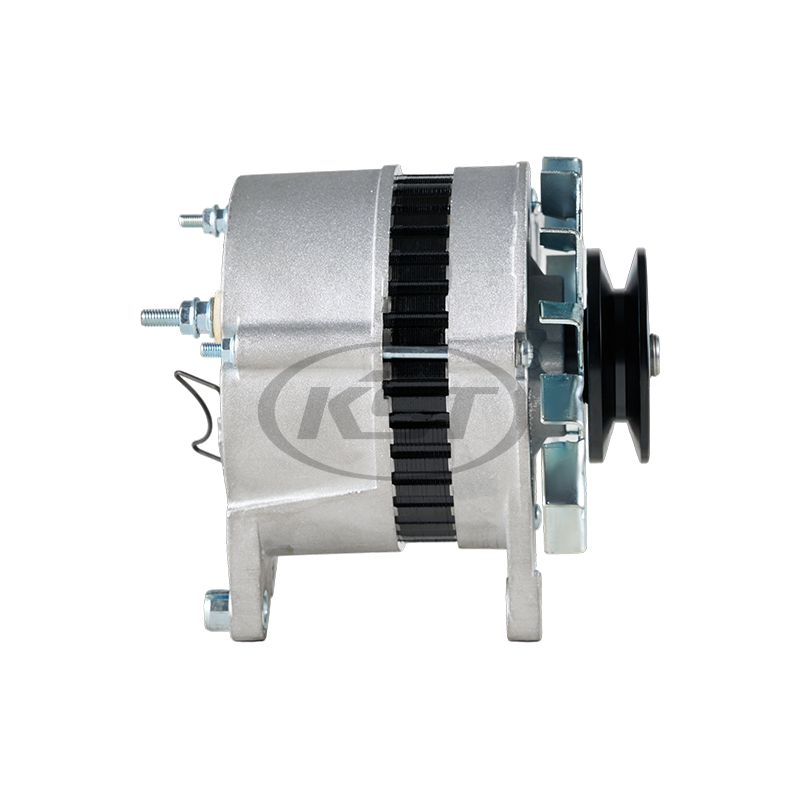

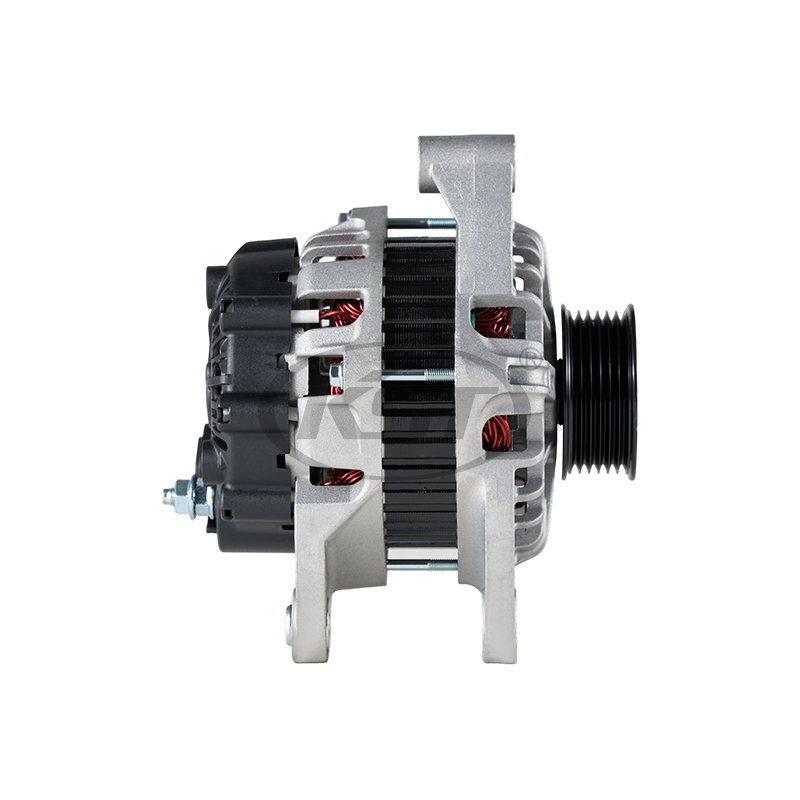

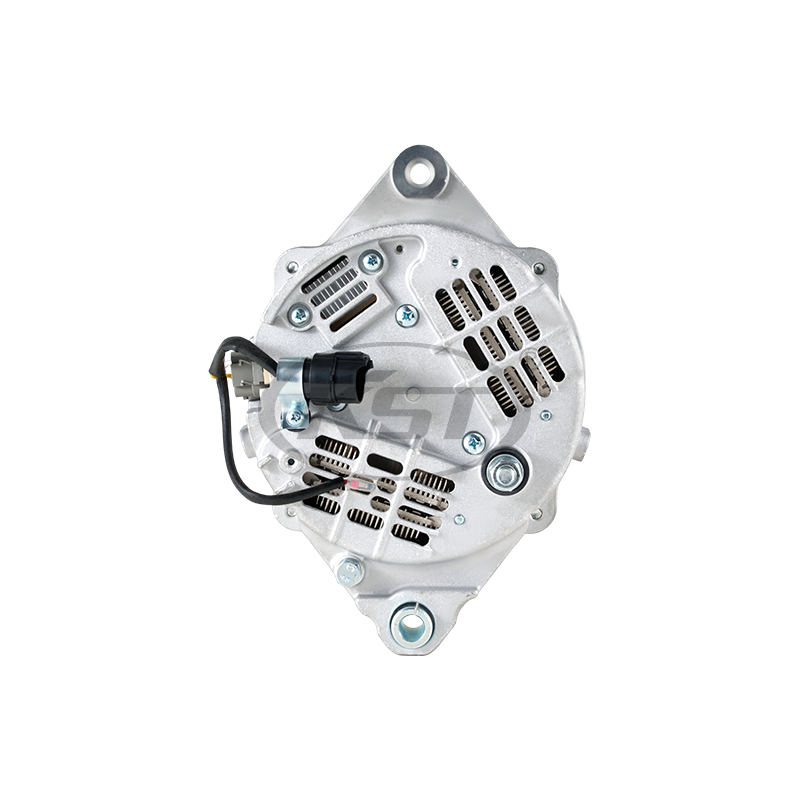

As an OEM Alternator Manufacturer, we focus on designing Construction Vehicle Alternator and Construction Machinery Alternator solutions that meet the continuous power demands of modern equipment. Every Excavator Alternator we produce is engineered to balance electrical stability, mechanical durability, and long service life under real construction site conditions.

Excavator Alternator Stability Under Long Working Hours

Long operating hours are a defining characteristic of excavators. From a factory standpoint, Excavator Alternator stability depends on thermal control, winding efficiency, and voltage regulation accuracy.

Key engineering considerations include:

- High-efficiency copper windings to reduce electrical resistance and heat buildup

- Optimized cooling airflow paths that maintain consistent output during extended operation

- Precision voltage regulators that stabilize charging even when electrical loads fluctuate

A well-designed Excavator Alternator maintains constant output throughout long shifts, preventing battery over-discharge and protecting onboard electronics. In our production lines, each Excavator Alternator is tested under simulated long-duration loads to verify endurance. For machines operating continuously, a reinforced Construction Machinery Alternator structure ensures minimal performance drop over time.

Can Construction Alternators Handle High Vibration Conditions?

Construction environments expose machines to constant shock and vibration. A reliable Construction Vehicle Alternator must be mechanically reinforced to survive these stresses without internal damage.

From the manufacturing side, vibration resistance is achieved through:

- Heavy-duty bearing systems with enhanced radial load tolerance

- Secure internal component fixation to prevent coil or regulator movement

- Rigid housing design that minimizes structural deformation

Each Construction Vehicle Alternator is subjected to vibration simulation tests that replicate real jobsite conditions. By pairing mechanical strength with electrical precision, manufacturers ensure that alternator performance remains stable even when mounted on heavily vibrating equipment. Proper vibration resistance also extends the service life of the charging system and reduces maintenance frequency.

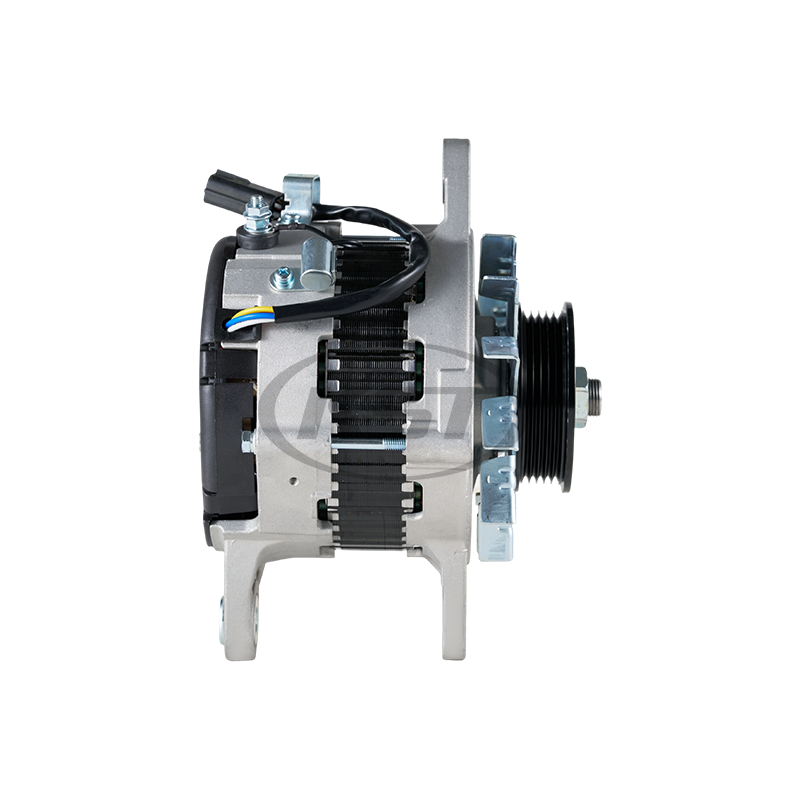

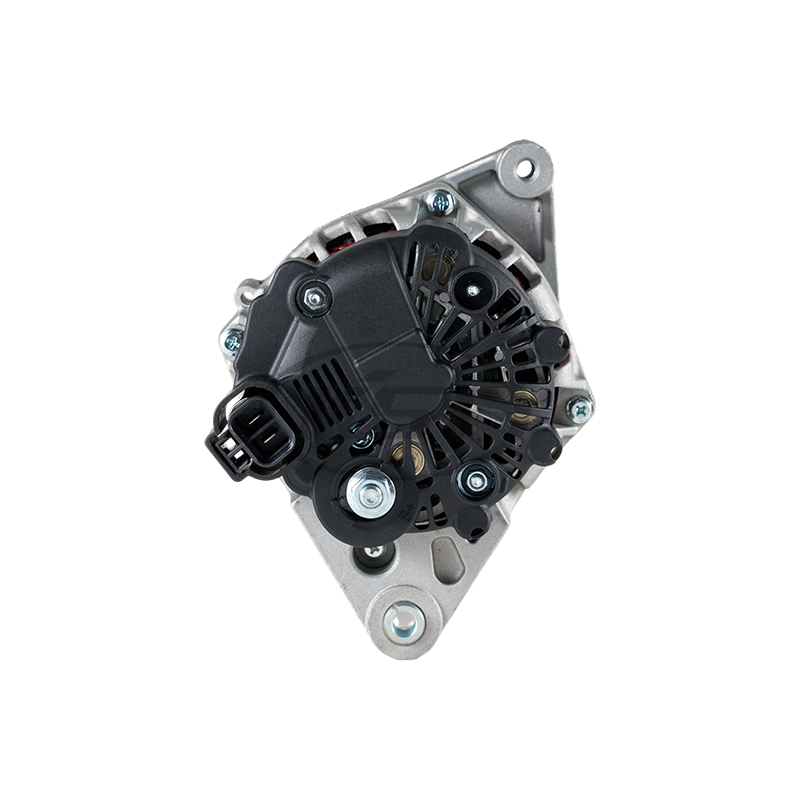

Excavator Alternator Suitable for Tropical or Cold Climates?

Climate adaptability is a major concern for global markets. An Excavator Alternator used in tropical regions faces high humidity and heat, while cold climates demand reliable output at low temperatures.

To address this, manufacturers implement:

- Moisture-resistant insulation coatings to prevent corrosion in humid environments

- Temperature-stable electronic components that function across wide thermal ranges

- Cold-start optimized output curves for reliable charging in low temperatures

A climate-adapted Construction Machinery Alternator ensures consistent power supply regardless of environmental extremes. In production, climate simulation chambers allow testing under both heat and cold cycles, confirming durability before shipment. This approach enables alternators to perform reliably in diverse global construction conditions.

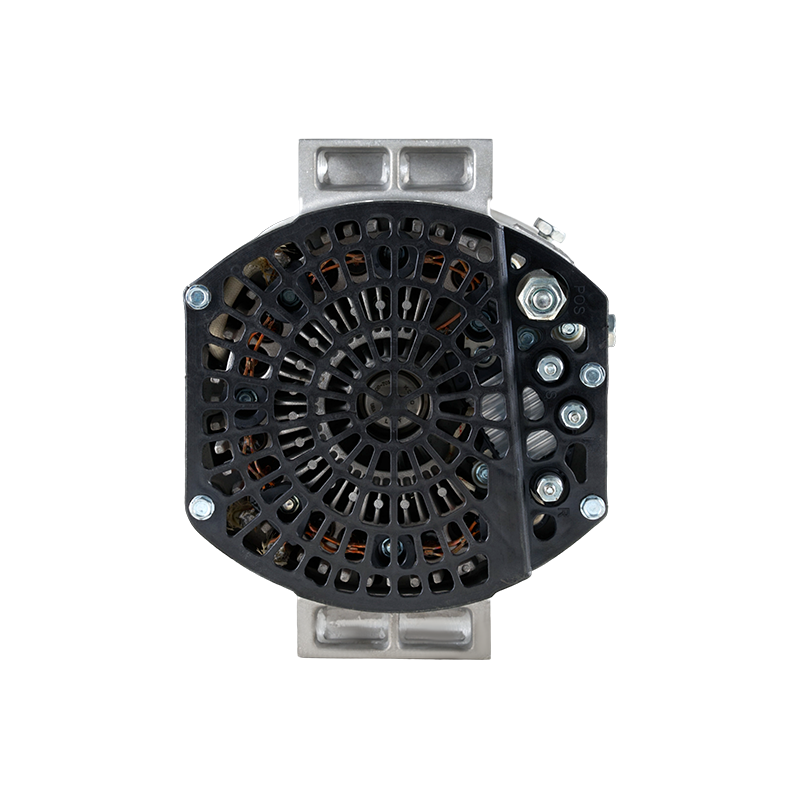

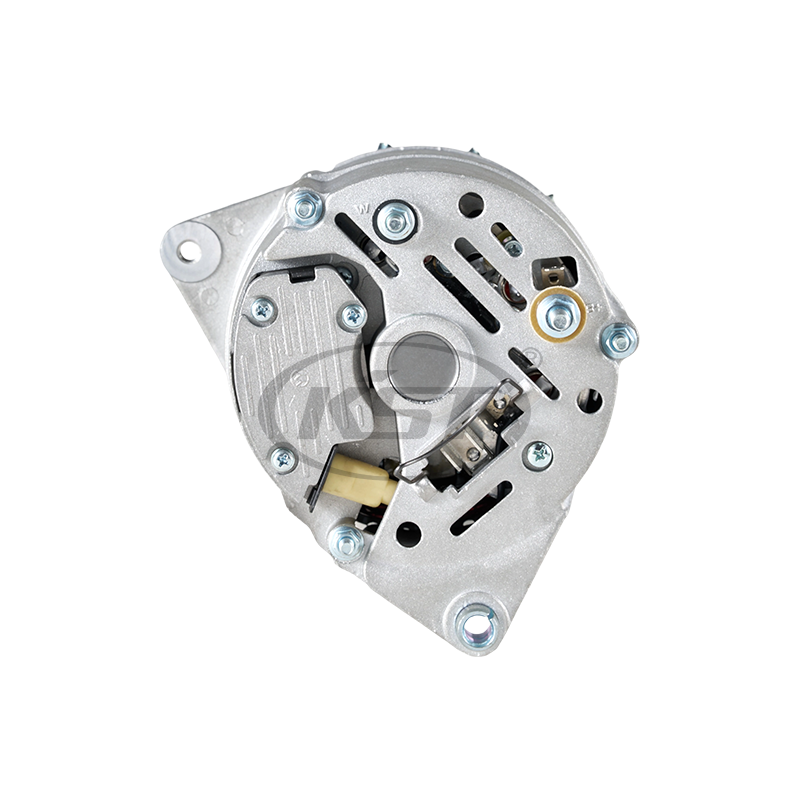

Internal Regulator Alternator for Construction Vehicles Advantages

An internal regulator design is increasingly preferred in modern equipment. For a Construction Vehicle Alternator, integrating the regulator inside the unit offers both functional and operational advantages.

Main benefits include:

- Simplified wiring systems, reducing installation errors

- Improved voltage response speed during sudden load changes

- Enhanced protection against dust and moisture

From an OEM Alternator Manufacturer perspective, internal regulation also improves consistency across production batches. By reducing external dependency, the alternator becomes a more self-contained and reliable power unit. This design is especially beneficial for construction vehicles operating in remote or harsh environments where maintenance access is limited.

Pre-Shipment Testing Process for Alternators

Quality assurance is a critical responsibility of a professional OEM Alternator Manufacturer. Before delivery, every Construction Machinery Alternator undergoes a structured testing process to ensure compliance with performance and durability standards.

Typical testing stages include:

| Test Stage | Purpose |

| Load output testing | Verify stable current under varying electrical demand |

| Thermal aging test | Confirm heat resistance during extended operation |

| Noise and vibration check | Ensure smooth mechanical performance |

| Final functional inspection | Validate overall charging efficiency |

Each Construction Machinery Alternator is approved only after passing all stages. This systematic testing approach ensures consistent performance and minimizes failure risks in the field. For buyers, this process translates into dependable alternators with predictable service life.

From long-hour stability to climate adaptability and vibration resistance, alternator performance is the result of deliberate engineering and strict quality control. A dedicated OEM Alternator Manufacturer does more than assemble components—it designs power solutions tailored to construction realities. By combining advanced testing, structural reinforcement, and intelligent regulation, manufacturers deliver alternators that support equipment reliability across diverse applications and environments.

en

en  English

English عربى

عربى فارسی

فارسی

+86-18967073588

+86-18967073588