Maintaining Electric Producing Motor equipment is essential to ensure safety, efficiency, and long-term performance. Proper maintenance reduces unexpected downtime, extends the motor's life, and keeps your Electric Motor Equipment operating at peak efficiency. But what exactly does maintenance involve, and how often should it be performed?

Electromechanical Motors are critical components in industrial, commercial, and residential applications. Neglecting their upkeep can cause severe consequences, including mechanical breakdown, electrical failures, and safety hazards. Regular maintenance helps to:

- Prevent minor issues from becoming major problems

- Ensure stable electrical output and efficiency

- Protect other connected Electric Motor Equipment from damage

- Guarantee safe operation for personnel

In practice, lots of industrial Electric Producing Motors require daily, weekly, and annual maintenance routines depending on usage intensity and environmental conditions.

How Often Should an Electric Producing Motor Be Inspected?

The frequency of inspection for Electric Producing Motor and Electromechanical Motor depends on:

- Operating environment (dust, moisture, temperature)

- Duration of daily operation

- Load variations

- Type of Electric Motor Equipment

For motors operating in clean environments, weekly visual inspections may suffice. For motors in dusty, humid, or corrosive environments, inspections should occur daily. In addition, an annual overhaul is recommended to ensure all components are in top condition.

Keeping Electric Motor Equipment clean prevents overheating and reduces wear. Proper cleaning includes:

Remove dust, sludge, and debris from the motor base and housing. In dusty environments, cleaning should be performed daily to prevent accumulation that may affect airflow and cooling.

Inspect motor terminals for loose or burnt screws. Dust and corrosion on connections can reduce conductivity and increase heat, potentially damaging your Electric Producing Motor.

- Starting Device Cleaning:

Dust and dirt may accumulate on the motor's starting system. Clean contacts and wiring, ensuring the grounding wire is intact. This prevents sparks, short circuits, and unexpected malfunctions.

How Should Mounting Screws and Bearings Be Checked?

Loose components are a common cause of Electromechanical Motor failure. Routine checks should cover:

- Mounting Screws: Ensure anchor screws, end cap screws, and bearing cap screws are tight. Loose fasteners can cause vibration and mechanical stress.

- Bearings: Bearings should be inspected for wear, cleaned, and lubricated with fresh grease or oil. The interval for lubrication usually ranges from 3 to 6 months but can be shorter in high-temperature or dusty environments. Proper lubrication ensures smooth rotation of the Electric Producing Motor and protects connected Electric Motor Equipment.

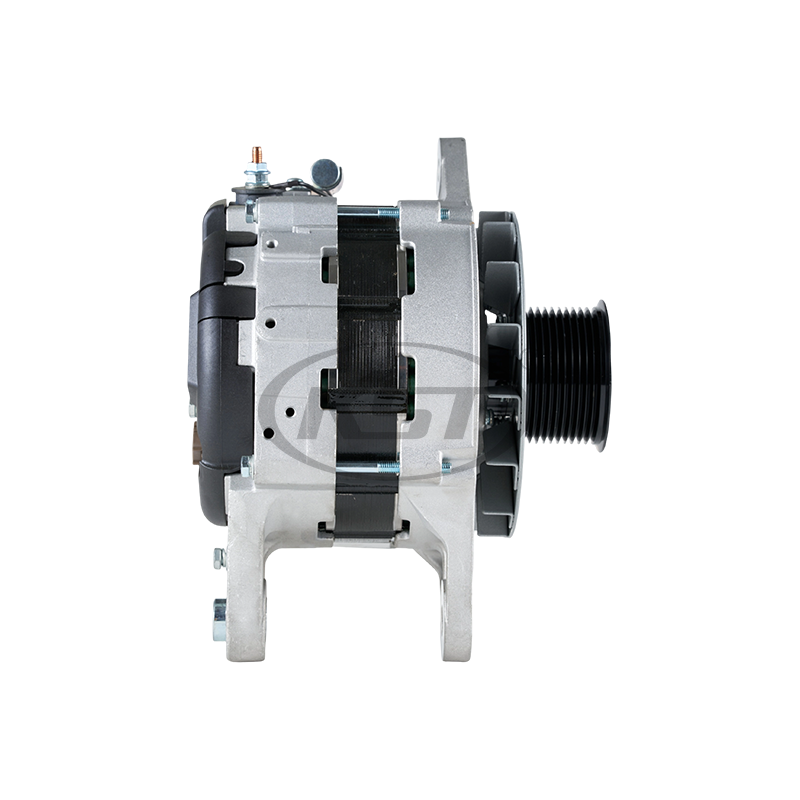

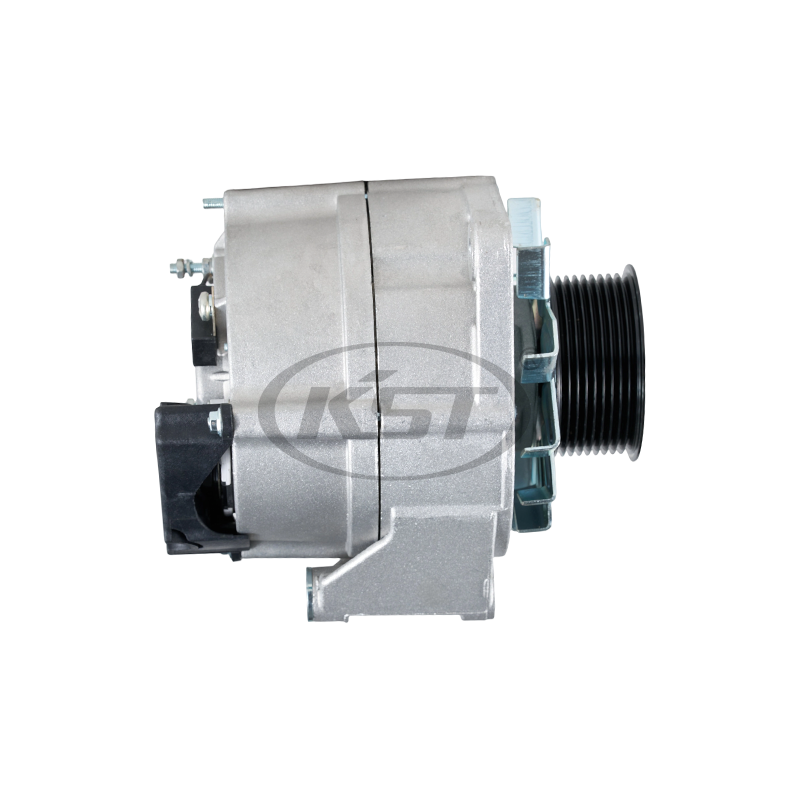

How to Inspect Transmission Systems?

Most Electromechanical Motors are connected to pulleys, couplings, or belts. Regular inspection involves:

- Checking pulleys and couplings for wear or damage

- Ensuring belts are intact and properly tensioned

- Verifying secure attachment to the motor shaft

Neglecting transmission maintenance can cause vibration, misalignment, or even catastrophic equipment failure.

How Is Insulation Maintained in Electric Producing Motors?

Insulation is critical to the safe operation of Electric Motor Equipment. Problems often arise due to moisture, dust, or corrosive gases. Key steps include:

- Dryness Check: Humid conditions reduce insulation resistance, increasing the risk of electrical faults.

- Resistance Testing: Measure insulation resistance regularly to detect deterioration.

- Grounding Verification: Ensure the motor housing is properly grounded to prevent accidental shocks or short circuits.

Regular insulation checks prevent winding faults, protect personnel, and maintain stable performance of your Electromechanical Motor.

What Maintenance Is Required for Motor Terminals and Wiring?

Electrical connections are the lifelines of Electric Producing Motor operation. Maintenance steps include:

- Tightening terminal screws

- Cleaning corrosion and dust

- Checking for burnt or damaged wires

- Confirming proper grounding

These steps reduce resistance and prevent voltage drops, which can adversely affect Electric Motor Equipment and downstream systems.

How Should High-Voltage Motors Be Overhauled?

An annual overhaul is critical for comprehensive maintenance of Electromechanical Motors. During an overhaul, technicians should:

- Disassemble the motor and remove all dust and debris

- Inspect all components for wear or damage

- Clean and lubricate bearings

- Test insulation and electrical continuity

- Replace any missing or worn parts

Overhauls restore Electric Motor Equipment to good performance and extend the motor's lifespan, reducing long-term maintenance costs.

How Can Operating Environment Affect Maintenance Schedules?

The environment in which Electric Producing Motors operate greatly influences maintenance frequency:

- Dusty conditions: Require daily cleaning

- High temperature: Shorten lubrication intervals for bearings

- Humid or corrosive gases: Increase insulation checks and terminal cleaning

- Continuous operation: Necessitates more frequent monitoring of voltage, temperature, and mechanical wear

Adapting your maintenance schedule to environmental conditions ensures that your Electromechanical Motor and Electric Motor Equipment remain reliable and safe.

What Are Simple Daily Checks for Electric Motor Equipment?

Even between detailed inspections, daily checks are essential:

- Observe abnormal noise or vibration

- Check for overheating of housing or terminals

- Verify indicator lights and warning systems

- Ensure clean and clear airflow for cooling

These simple actions help detect early signs of trouble before they develop into major failures.

Why Is Lubrication Critical for Electric Producing Motors?

Bearings are often stressed components in Electromechanical Motors. Proper lubrication:

- Reduces friction and wear

- Prevents overheating

- Extends service life of bearings and connected Electric Motor Equipment

Choosing the correct type of grease or oil, and adhering to lubrication intervals, ensures smooth operation and energy efficiency.

How Does Regular Maintenance Improve Efficiency?

Proper maintenance of Electric Producing Motors directly affects operational efficiency:

- Reduces electrical losses due to poor connections

- Maintains good insulation resistance

- Ensures bearings and mechanical components rotate smoothly

- Prevents energy waste from overheating or vibration

Well-maintained Electromechanical Motor systems contribute to lower operating costs and improved overall performance of Electric Motor Equipment.

How Can Maintenance Prevent Safety Hazards?

Electrical and mechanical failures in Electric Producing Motors can be dangerous. Regular maintenance:

- Detects insulation faults before grounding occurs

- Prevents overheating and fire risks

- Ensures secure mounting and mechanical integrity

- Keeps emergency systems functional

Safety is a primary reason to maintain Electric Motor Equipment consistently and systematically.

Good Practices for Maintaining Electric Motor Equipment

Effective maintenance of Electric Producing Motors and Electromechanical Motors includes:

- Cleaning and inspecting motor exteriors and terminals

- Checking mechanical fasteners, bearings, and transmission systems

- Monitoring insulation resistance and electrical connections

- Performing annual overhauls for complete inspection and servicing

By following these practices, you ensure your Electric Motor Equipment operates safely, reliably, and efficiently, providing years of dependable service.

Why Is Maintenance Planning and Record-Keeping Important?

Maintaining Electric Producing Motor and Electromechanical Motor systems is not only about physical checks; keeping detailed records of inspections, lubrication, and repairs ensures consistency and accountability. Documenting maintenance schedules for all Electric Motor Equipment helps track component lifespan, predict potential failures, and plan replacements proactively. This approach also allows technicians to analyze trends, identify recurring issues, and optimize maintenance intervals. Proper planning and record-keeping ultimately enhance safety, reliability, and operational efficiency of all connected Electric Producing Motors.

en

en  English

English عربى

عربى فارسی

فارسی